Retrofitting

Our approach

Over time automation systems become obsolete, spare parts become expensive and difficult to obtain and most importantly hardware and software technology advances. In traditional Process Control Systems and especially in older systems plants must “live” with many problems such as:

- Unstable steam production

- Large swings in steam production

- Periods of significantly reduced steam production

- Oscillations in primary air supply

- Oscillations in secondary air supply

- Oscillations in flue gas temperature

- Poor waste combustion – large amount of total organic carbon TOC

- Slagging and fouling of the combustor

- Significant increases in consumption of chemicals for flue gas cleaning

- Large quantity of fly ash produced

- More reliance on operator intervention in the control room

- More stress in control room because of alarms caused by process variability

By retrofitting the latest state-of-the-art combustion control technology many of these problems will simply disappear.

Our technical experts can assess your plant and using our many years of combustion expertise we can advise:

- How the control system can be upgraded, if fundamental changes are required or whether a combustion optimization system can be added

- Identify where the problems are in the combustion control system

- Identify if mechanical changes are required and how this will improve the system response

- Outline the benefits of replacing the grate with a grate using a different control method

Technikgruppe‘s Technical Experts have almost 30 years of experience in modernizing and developing the control and automation of the combustion process in Energy from Waste and biomass plants. As an INDEPENDENT ADVISOR Technikgruppe can offer:

- Consulting:

For retrofitting and modernization of old plants

For combustion optimization

For use of different combustion technologies

For analysis of types of grates and feasibility of replace with different types of grate

For construction of new plants

- Feasibility studies

- Training and Education through:

Personal on-site training

Seminars

Webinars or video conferences

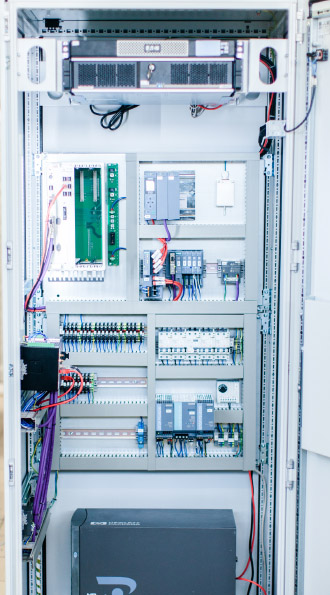

- Engineering

- Installation of equipment

- Service