Introduction

Technology of fire

The combustion process in Energy from Waste and biomass plants is very complex, and the demands on control systems in those plants are also very complex. There are many theories about the best combustion technologies to use and there are equally many different approaches to find the right solutions.

In most conventional control systems, there are many control algorithms which are implemented and many arguments how to compare different approaches to make a real difference. In all of these discussions there are two basic factors that are used in nearly all comparisons:

- What main actions – have influence on – the quality of the combustion process?

- Which measured parameters can be accurately compared to estimate the combustion quality?

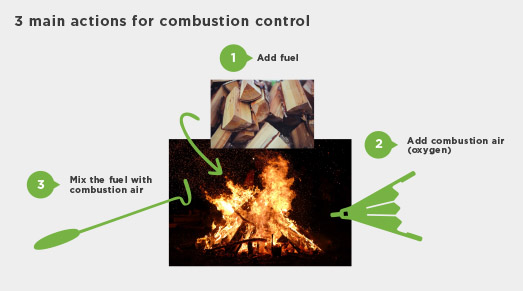

Simplistically there are 3 main actions which have influence on combustion process.

- Adding fuel into a burning chamber

- Blowing oxygen into the fire

- Mixing the fuel with combustion air

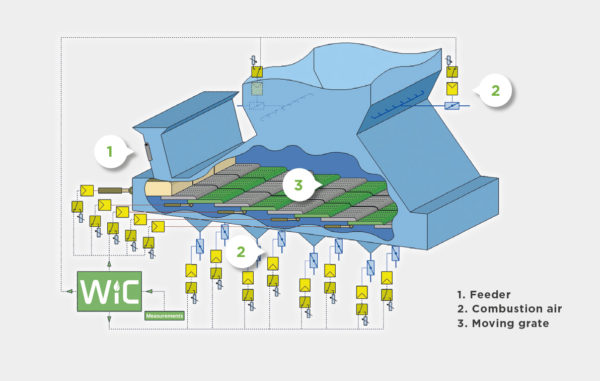

After many years of experience in optimizing the combustion processes in Waste and Biomass plants, we have demonstrated that mixing the burning fuel is one of the most important actions inside the combustor, and is especially effective with special FORWARD MOVING RECIPROCATING GRATES. Because of this, Technikgruppe´s combustion controller (WiC combustion manager) is primary developed for implementing on FORWARD MOVING RECIPROCATING GRATES.

WiC is our very unique product using state-of-the-art software and high-speed controllers to achieve

great combustion optimization.

WiC is simple to implement and can either be retrofitted as a “by-pass” system to any existing DCS control system, or it can be integrated into the DCS during the development and construction of the new control system.