Combustion optimisation

Basics

The combustion process on forward moving reciprocating grates is very complex and the quality of combustion has considerable influence on the profitability, reliability and availability of Energy-from-Waste plants. Good combustion will lead to financial benefits. There are many different combustion control systems on the market using different principles for combustion control with different results.

Some systems have HI TECH measurement equipment and provide additional information about the combustion process, but in most cases such information has little or no effect on the enhancement of combustion stability.

For a better understanding of the assessment of the quality of the combustion system it is essential to analyze:

- Which actions have an influence on the combustion?

- Which process values are relevant for the assessment of the combustion system?

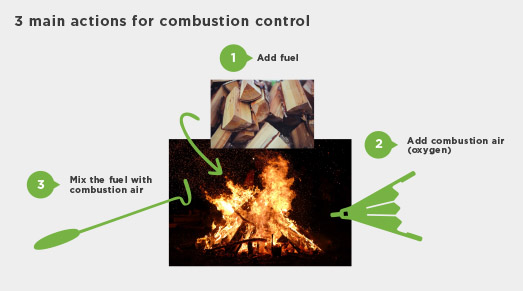

Just 3 main actions

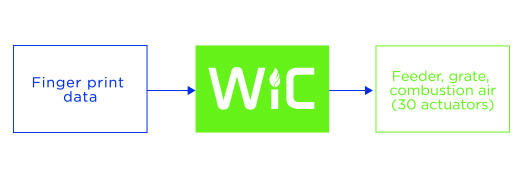

The basic working principle of the WiC combustion manager is based on 3 main actions:

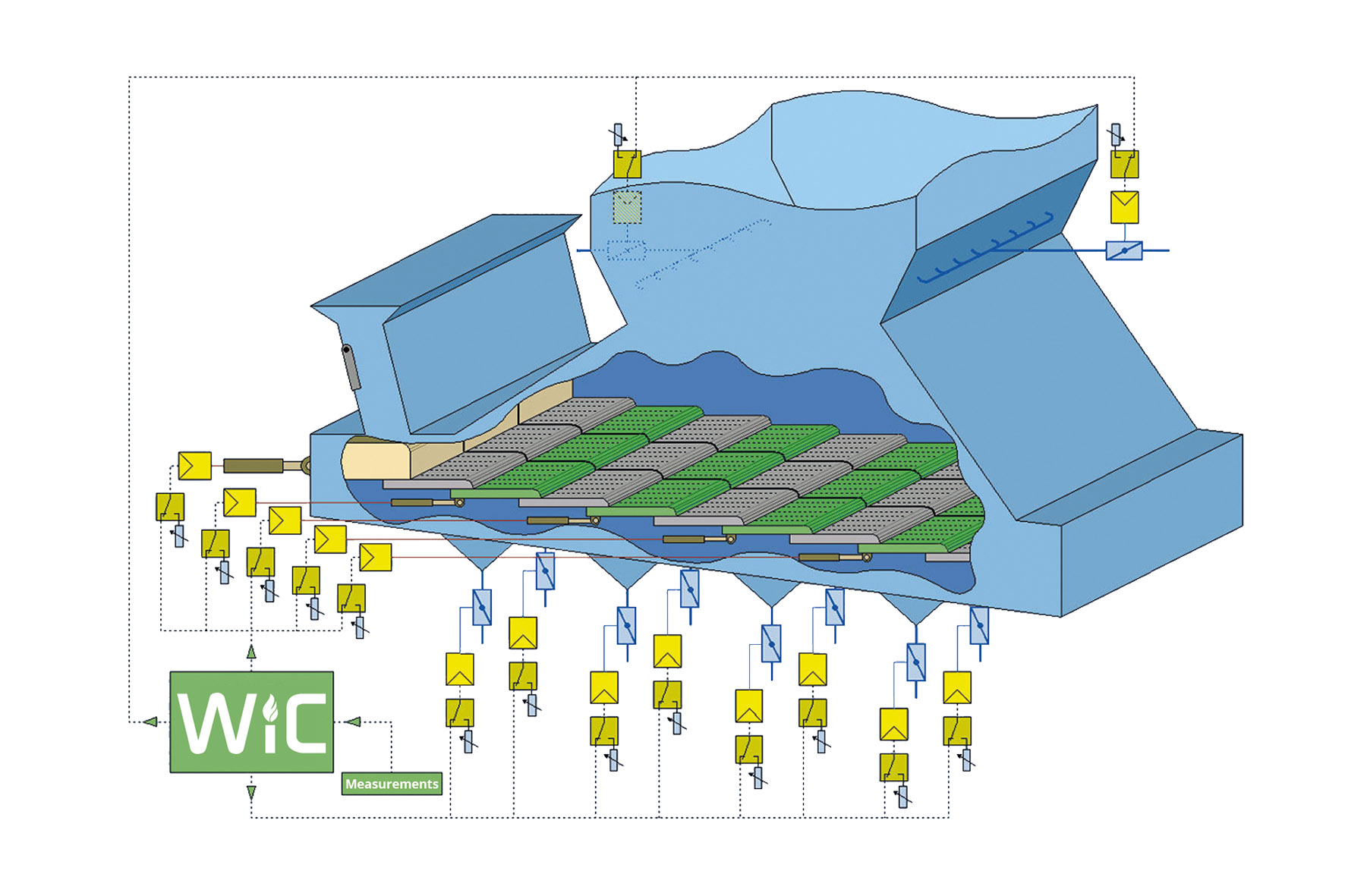

WiC has influence on feeding of fuel (feeder), adding in combustion air (primary and secondary air) and mixing the fuel with combustion air (movement of grate).

Modern systems have about 30 actuators at their disposal. These 30 actuators allow billions of combinations for controlling the combustion process.

30 actuators » billions of combinations

The main task in modern combustion control is:

- to calculate the appropriate combination – one out of billions

- to find out the relevant process values for checking the quality of combustion control

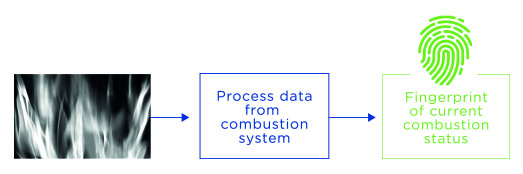

Modern measurement systems in Energy-from-Waste plants provide more than 100 process values for the combustion process. These 100 process values are the fingerprint of the combustion process.

Selecting „The One“ out of billions

With appropriate algorithms, utilizing the fingerprint, it is possible to calculate an optimum combination (one of billions) and thereby optimize the combustion process. These algorithms are all integrated in the WiC-combustion manager, relying on more than 25 years of experience.

According to process values from the combustion process TG developed algorithms to calculate appropriate combinations and in that way optimize the combustion. These calculations are very robust and proven in many EfW plants.

Just standard instrumentation

The algorithms used by WiC do not need any implementation of pyrometers or thermal cameras. The implementation of a thermal camera can provide additional information, but this information is not used (because too inexactly and therefore not needed) in WiC algorithms for combustion optimization. It may only be utilzed for detecting bad burn out and as a trigger for counter measures.

The WiC just needs standard process instrumentation, no „tricky equipment“ like thermal cameras or pyrometers is required.

Which combustion parametes have to be analized and why?

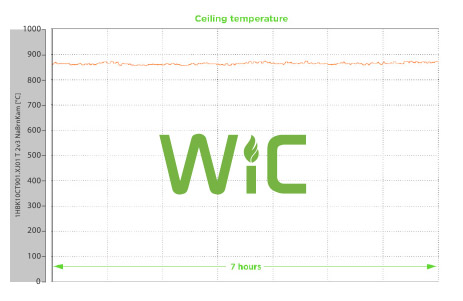

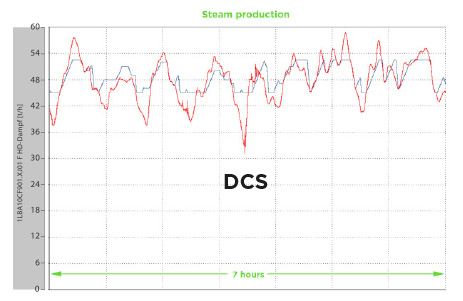

Steam production diagram with DCS combustion control.

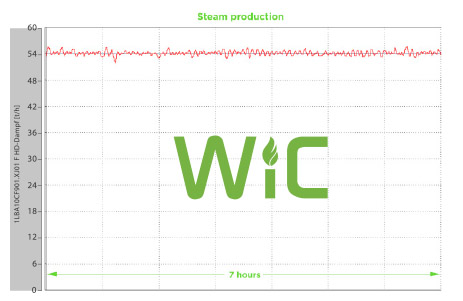

Steam production diagram with WiC combustion control.

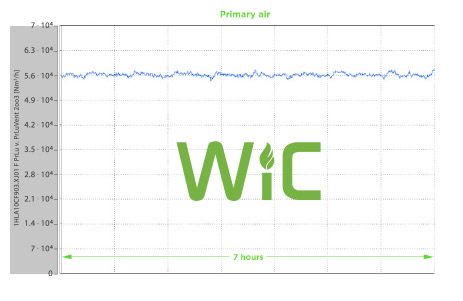

Note: WiC at the same time provides also stabilization of primary and secondary air flow!

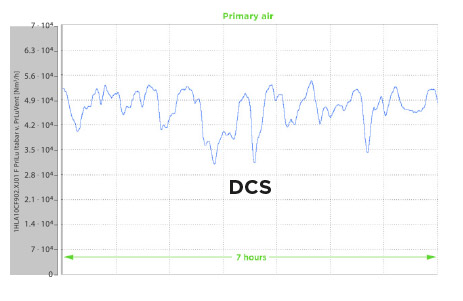

Primary air flow controlled by DCS.

Primary air flow controlled by WiC.

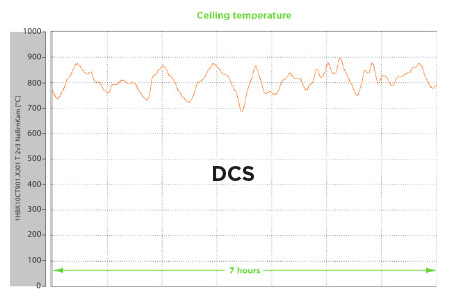

Flue gas temperature with DCS control.

Flue gas temperature with WiC control.